This took a bit longer than the rest of the sides should take since today I spent some time making decisions about how I want to proceed.

Key points from this episode:

Hole sizes need to take into account the size of the screws

The screws need to be often enough to keep the perspex firmly pressed against the next surface, but not so many that the perspex or wood is unnecessarily weakened.

The edge is aligned towards the center. This may seem counter intuitive at first, but is so the puck has something to bounce against.

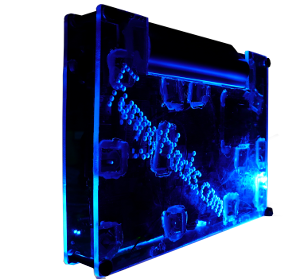

Above: Imported image from the old system

Above: Imported image from the old system

Above: Imported image from the old system

Above: Imported image from the old system